Schedule 80 CPVC Technical

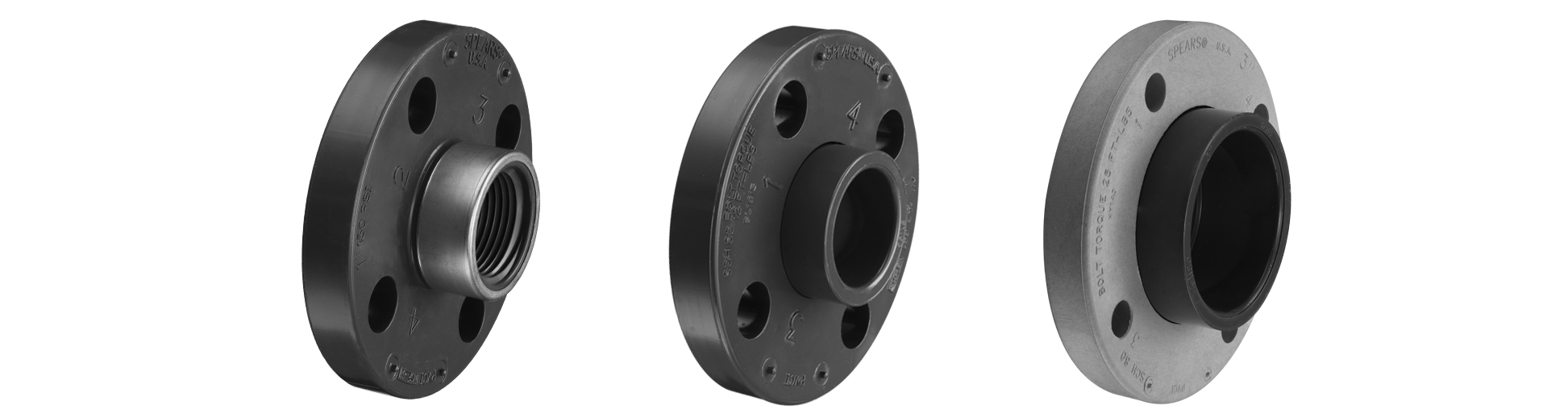

CPVC Pipe Flange Dimensions & Information

CPVC Pipe Flange Dimensions & Information

Print this Book

|

|

The information contained in this publication is based on current information and Product design at the time of publication and is subject to change without notification. Our ongoing commitment to product improvement may result in some variation. No representations, guarantees or warranties of any kind are made as to its accuracy, suitability for particular applications or results to be obtained therefrom. For verification of technical data or additional information not contained herein, please contact Spears® Technical Services Department [West Coast: (818) 364-1611 - East Coast: (678) 985-1263].

GENERAL INFORMATION

Recommendations For Installers And Users

Plastic piping systems should be ENGINEERED, INSTALLED, and OPERATED in accordance with ESTABLISHED DESIGN AND ENGINEERING STANDARDS AND PROCEDURES for plastic piping systems. Suitability for the intended service application should be determined by the installer and /or user prior to installation of a plastic piping system. PRIOR TO ASSEMBLY, all piping system components should be inspected for damage or irregularities. Mating components should be checked to assure that tolerances and engagements are compatible. Do not use any components that appear irregular or do not fit properly. Contact the appropriate manufacturer of the component product in question to determine usability.

Solvent Weld Connections - Use quality solvent cements and primers formulated for the intended service application, pipe size and type of joint. While the pipe and fitting materials may be compatible with the intended medium, the solvent cement may not be. Consult the manufacturer for suitability of use. Read and follow the cement and primer manufacturers' applications and cure time instructions thoroughly. Be sure to use the correct size applicator.

Threaded Connections - Use a quality grade thread sealant. WARNING: SOME PIPE JOINT COMPOUNDS OR PTFE PASTES MAY CONTAIN SUBSTANCES THAT COULD CAUSE STRESS CRACKING TO PLASTIC. Spears® Manufacturing Company recommends the use of Spears® BLUE 75™ thread sealant which has been tested for compatibility with Spears® products. Please follow the sealant manufacturer's application/installation instructions. Choice of an appropriate thread sealant other than those listed above is at the discretion of the installer. 1 to 2 turns beyond FINGER TIGHT is generally all that is required to make a sound plastic thread connection. Unnecessary OVERTIGHTENING will cause DAMAGE TO BOTH PIPE AND FITTING.

"Lead Free" low lead certification - unless otherwise specified, all Spears® Thermoplastic Flanges specified here-in are certified by NSF International to ANSI/NSF® Standard 61, Annex G and is in compliance with California's Health & Safety Code Section 116825 (commonly known as AB1953) and Vermont Act 193. Weighted average lead content <=0.25%.

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fabricated Flange Technical Information

Application

Fabricated IPS and PIP Flange fittings are coupling devices designed for joining IPS (Iron Pipe Size) or PIP (Plastic Irrigation Pipe) plastic piping systems, where frequent disassembly may be required. These flanges can be used as transitional fittings for joining

IPS-to-IPS, PIP-to-PIP, IPS-to-PIP, or plastic to metal piping systems. Suitability of application is at the discretion of the user.

Pressure Rating

All standard fabricated flanges are Van Stone Style (except blind flange) - two piece design with rotating flange ring.

Class 150 IPS Flanges (with steel ring): 150 psi, water at 73°F.

IPS Flanges 18" - 24" (with plastic ring): 50 psi, water at 73°F.

IPS Flanges, Class 300 Bolt Pattern (with plastic ring): 1/2" - 16" 150 psi, 18" - 24" 50 psi, water at 73°F.

Blind Flanges, 14" - 24": 50 psi, water at 73°F.

PIP Flanges, 6" - 16" (with plastic ring & molded IPS flanges w/PIP Adapters): 125 psi, water at 73°F.

PIP Flanges, 18" - 24" (with steel ring): 125 psi, water at 73°F.

Flange Types

Van Stone Style Class 150 IPS (with steel ring) - Fabricated CPVC body with steel flange ring, available in sizes 18" through 24", slip socket and 14" through 24", spigot.

Van Stone Style IPS (with plastic ring) - Fabricated CPVC body with PVC flange ring, available in sizes 18" through 24", slip socket and 14" through 24", spigot.

Van Stone Style PIP (with plastic ring) - PIP adapter fabricated to injection molded CPVC Van Stone Style IPS flange, available in sizes 6" through 16", slip socket.

Van Stone Style PIP (with steel ring) - Fabricated CPVC body with steel flange ring, available in sizes 14" through 24", slip socket.

Blind - Closed ring design for capping off a mating flange; fabricated CPVC available in sizes 5" and 14" through 24".

Special Note On PIP Flange Sizes

In order to facilitate connections between IPS and PIP systems, all Plastic Irrigation Pipe flanges are fabricated with PIP sockets using standard IPS Flange Rings. These are indicated in dimension tables under "Size" as (nominal IPS flange size) x (actual PIP O.D.), such as: 6" x 6.140".

To better meet user needs, Spears® offers flanges for 15.300" O.D. PIP with either 14" or 16" IPS Flange Rings. In addition, both 18.360" and 18.701" O.D. PIP are offered with 18" IPS Flange Rings.

Materials

All fabricated flanges are produced from CPVC materials approved for potable water use by the National Sanitation Foundation (NSF®).Steel flange rings are carbon steel.

Conformance Standards

Materials - ASTM D 1784 (CPVC Cell Classification 23447-B).

Weights & Dimensions

Specified minimum bolt lengths are based on the use of two Spears® Flanges, two standard flat washers, standard nut and 1/8" thick elastomer full face gasket. Mating with other brands or accessories may require variations.

Note: Bolts and gaskets are not supplied with flanges. Dimension references:

L = Overall length of hub, ± 1/2 inch.

M = Outside diameter of socket hub, ± 1/4 inch.

N = (Laying Length) socket bottom to seal-ring face of

flange, ± 1/2 inch. R = Height (thickness) of flange ring, ± 1/16 inch.

Max O.D. = Outside diameter of ring, ± 1/16 inch.

Bolt Circle Diameter = ANSI B 16.5 Standard; ASTM D 4024, ± 1/16 inch.

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||